Introduction

Investing in a second-hand excavator can be a cost-effective solution for your construction or industrial projects. However, to ensure that your used excavator remains efficient and reliable, proper maintenance is essential. Regular maintenance not only extends the life of your machine but also helps in preventing unexpected breakdowns and costly repairs. In this comprehensive guide, we will share detailed maintenance tips that will help you maximize the performance and lifespan of your used excavator.

The Importance of Regular Maintenance

Before diving into specific maintenance tips, it’s important to understand why regular maintenance is crucial for your excavator. Like any heavy machinery, excavators are subject to wear and tear due to their demanding tasks. Regular maintenance ensures that the machine components are in good working condition, reduces the risk of major failures, and enhances the overall productivity of your operations. Moreover, well-maintained equipment often has a higher resale value.

- Regular Inspections

Daily Inspections

Performing daily inspections is a fundamental aspect of excavator maintenance. Before starting the machine, conduct a visual check to identify any obvious issues such as fluid leaks, loose bolts, or damaged parts. Check the condition of the tracks and undercarriage, and look for any signs of wear or damage.

Weekly Inspections

In addition to daily checks, a more thorough inspection should be carried out weekly. This includes checking the hydraulic system for leaks or damage, inspecting the condition of the bucket and attachments, and examining the engine and cooling system for any potential problems.

Monthly Inspections

Monthly inspections should include a detailed examination of all major components. Check the oil and fuel filters, inspect the air intake system, and ensure that the electrical system is functioning properly. Pay special attention to the undercarriage, as it is prone to significant wear.

- Clean the Undercarriage

The undercarriage is one of the most critical and heavily used parts of an excavator. It is constantly exposed to dirt, mud, rocks, and debris, which can cause accelerated wear if not cleaned regularly. Here are some tips for maintaining the undercarriage:

Regular Cleaning

After each use, especially in muddy or rocky conditions, clean the undercarriage to remove any accumulated debris. Use a pressure washer to clean hard-to-reach areas and ensure that the track components are free from dirt and debris.

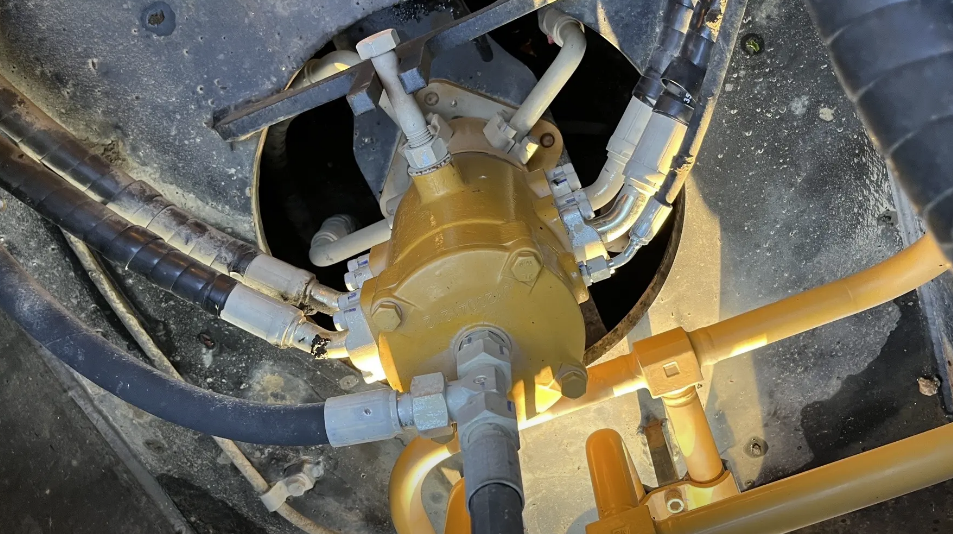

Inspections and Adjustments

Regularly inspect the undercarriage for signs of wear or damage. Check the track tension and adjust it according to the manufacturer’s specifications. Proper track tension is crucial for efficient operation and to prevent excessive wear on the track components.

Lubrication

Lubricate the track rollers, idlers, and sprockets to reduce friction and wear. Follow the manufacturer’s guidelines for the recommended type and frequency of lubrication.

- Monitor Fluid Levels

Maintaining proper fluid levels is essential for the smooth operation of your excavator. This includes engine oil, hydraulic fluid, coolant, and fuel. Here’s how to ensure that your machine’s fluid levels are always optimal:

Engine Oil

Regularly check the engine oil level and condition. Use the dipstick to ensure that the oil is within the recommended range. Change the engine oil and filter at the intervals specified by the manufacturer. Using the correct type of oil is crucial for the engine’s longevity.

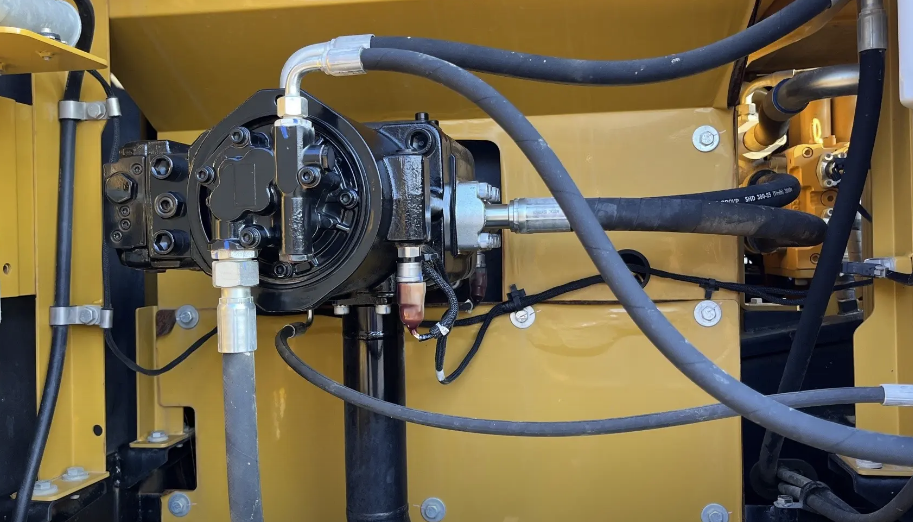

Hydraulic Fluid

Hydraulic fluid is the lifeblood of your excavator’s hydraulic system. Check the hydraulic fluid level regularly and top it up if necessary. Inspect the hydraulic lines and connections for leaks or damage. Replace the hydraulic fluid and filters according to the manufacturer’s maintenance schedule.

Coolant

The coolant helps regulate the engine temperature and prevent overheating. Check the coolant level in the radiator and the coolant reservoir. Ensure that the coolant mixture is correct and that there are no leaks in the cooling system. Flush and replace the coolant at the intervals recommended by the manufacturer.

Fuel

Use clean, high-quality fuel to prevent engine problems. Check the fuel level before each use and ensure that the fuel tank cap is securely in place to prevent contamination. Regularly inspect the fuel lines and filters for any signs of damage or clogging.

4. Grease Moving Parts

Lubrication is crucial for reducing friction and wear on moving parts. Regularly greasing the joints, pins, and bushings helps ensure smooth operation and prolongs the life of these components. Here are some tips for effective lubrication:

Use the Right Grease

Different components may require different types of grease. Refer to the manufacturer’s recommendations for the correct type of grease to use for each component.

Grease Points

Identify all the grease points on your excavator. These typically include the boom, arm, bucket linkage, swing bearing, and undercarriage components. Ensure that you apply grease to all these points regularly.

Frequency

The frequency of lubrication depends on the operating conditions and the manufacturer’s recommendations. In harsh conditions, more frequent greasing may be necessary. Always follow the manufacturer’s guidelines for lubrication intervals.

5. Replace Filters

Filters play a vital role in protecting your excavator’s engine and hydraulic system from contaminants. Dirty or clogged filters can lead to reduced performance and potential damage. Here’s how to manage your excavator’s filters:

Air Filters

Inspect the air filter regularly and replace it if it appears dirty or clogged. A clean air filter ensures that the engine receives a proper air supply, which is essential for efficient combustion and performance.

Fuel Filters

The fuel filter removes impurities from the fuel before it reaches the engine. Regularly check and replace the fuel filter to prevent contaminants from causing engine damage.

Hydraulic Filters

Hydraulic filters protect the hydraulic system from contaminants that can cause wear and damage. Replace the hydraulic filters at the intervals specified by the manufacturer to maintain the integrity of the hydraulic system.

6. Monitor Track Tension

Proper track tension is essential for efficient operation and to prevent excessive wear on the undercarriage components. Here’s how to maintain the correct track tension:

Regular Checks

Regularly check the track tension according to the manufacturer’s guidelines. The track should have a slight sag, usually about 1-2 inches, depending on the type of excavator.

Adjustments

Adjust the track tension using the tension adjustment mechanism provided by the manufacturer. Over-tightened tracks can cause excessive wear on the undercarriage, while loose tracks can lead to derailing and reduced efficiency.

Consider Operating Conditions

The operating conditions can affect the track tension. For example, working in muddy or sandy conditions may require more frequent adjustments. Always adjust the track tension to suit the specific conditions in which you are operating.

7. Protect from Harsh Elements

Exposure to harsh weather conditions can accelerate wear and damage to your excavator. Protecting your machine from the elements can help extend its life. Here’s how to do it:

Shelter

Whenever possible, store your excavator in a sheltered area, such as a garage or shed. This protects it from rain, snow, and extreme temperatures, which can cause rust and other damage.

Covers

If a sheltered area is not available, use a heavy-duty cover to protect your excavator from the elements. Ensure that the cover is properly secured and covers the entire machine.

Regular Cleaning

Regularly clean your excavator to remove any dirt, mud, or salt that can cause corrosion. Pay special attention to areas that are prone to rust, such as the undercarriage and joints.

8. Follow the Manufacturer’s Maintenance Schedule

Adhering to the manufacturer’s recommended maintenance schedule is crucial for prolonging the life of your excavator. Here’s why it’s important and how to do it:

Importance of the Maintenance Schedule

The manufacturer’s maintenance schedule is designed to ensure that all critical components are inspected, serviced, and replaced at the appropriate intervals. Following this schedule helps prevent major failures and keeps your machine in optimal condition.

Keeping a Maintenance Log

Maintain a detailed log of all maintenance activities. Record the date, the type of maintenance performed, and any parts that were replaced. This helps you keep track of what has been done and what needs to be done in the future.

Regular Updates

Regularly review and update your maintenance schedule based on the operating conditions and the machine’s performance. Adjust the intervals as necessary to ensure that your excavator receives the care it needs.

Conclusion

Maintaining your second-hand excavator doesn’t have to be a daunting task. By following these detailed maintenance tips, you can ensure that your machine remains reliable, efficient, and productive for years to come. Regular inspections, proper lubrication, fluid management, and adherence to the manufacturer’s maintenance schedule are key to extending the life of your excavator.

For more expert advice on maintaining your heavy equipment, visit our website or contact us today! We’re here to help you keep your machines running smoothly and efficiently, so you can focus on getting the job done.